ABOUT US

TAIKO DRUM INDUSTRIES IS A

MANUFACTURER OF HIGH-DENSITY

POLYETHYLENE (HDPE)

DRUMS USING STATE-OF-THE-ART TECHNOLOGIES

Whether for hazardous or non-hazardous products, our clients come from a wide range of industries, e.g. agricultural, food, chemical, pharmaceutical, oils, etc.

Established since 1981, Taiko Drum Industries Sdn Bhd has developed a team of factory staff and workers with experiences in the development of top class UN approved drums at our plant in Tangga Batu, Malacca. The Group has expanded with manufacturing plants in Jakarta and Surabaya, Indonesia and in 2013 has expanded into Thailand with the addition

of its latest plant located in Rayong.

With our extensive experience in technical development and manufacturing processes, we are a leading HDPE drum specialist in South East Asia, producing highest standard of quality. Consistency and reliability and comply with international safety requirement. Our drums are an excellent form of packaging for environmentally-friendly and safety-minded

customers.

OUR PRODUCTS

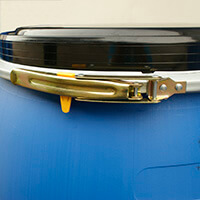

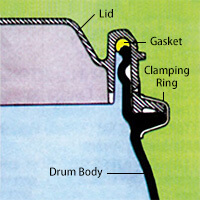

OPEN TOP DRUM

The user friendly Taiko Open Top drum comes in many sizes with

a snap lock metal gripper and stopper to act as a security seal for

better locking performance.

APPLICATION

UN approved for packaging higher viscosity chemicals, solid and

emulsion products. Excellent for storage of foodstuff in paste

form in a cold room at low temperatures. The removable cover is ideal for reworking and finishing work.

SIZE RANGE

30 ~ 214 litres

ADVANTAGES

1. Optimal draining and easy cleaning for multiple trips

Complete draining of the contents and easy cleaning are ensured

due to the smooth inner wall surface of the drum and lid.

2. Environmentally friendly

Complete removal of the content means less problems with

disposal at the end of the drumʼs useful life.

3. Inert, corrosion free

Minimal risk of product contamination. Proven in service

throughout the world, even under extreme climatic conditions and

also under harsh environments.

4. More efficient handling

Savings on filling and sealing costs.

5. Long service life

Drums can be reconditioned for reuse and have a relatively high

resale value. No repainting required.

6. Provision for venting

A venting valve enables the filling of drums with warm of hot fill

products up to 80°C without causing vacuum formation

(negative effect on stacking).

7. Easy stirring

The full opening makes it easy to use stirring equipment. This is

important for products with a tendency to settle or which have to

be provided with additives before processing such as paints,

wetting agents, dispersion agents, etc.

8. Product marking

The smooth drum lid/body offers a large solid surface for product

identification by labelling, stenciling or silkscreen printing.

TIGHTHEAD L-RING DRUM (SINGLE/DOUBLE LAYER)

The tighthead L-Ring HDPE drum is renowned internationally as

the most successful, large size blow moulded packaging product

using the single operation technology.

APPLICATION

UN approved for the storage and transportation of hazardous,

aggressive and non-hazardous chemicals worldwide by shippers

and transporters.

SIZE RANGE

209 ~ 235 litres

ADVANTAGES

1. Optimal draining

The optimally drainable L-Ring drum reduces liquid residue to

less than 100ml when emptied at an angle up to 20°resulting in

less wastage.

2. Easy cleaning for multi-trip use

The smooth, seamless walls and optimal draining make for quick

and thorough cleaning at lower cost.

3. Environmentally friendly

Minimal residue when drums are empty means easier recycling

and less problems with disposal at the end of the drumʼs useful

life.

4. Lower transportation cost

Lighter tare weight against metal drums means savings on

transportation cost.

5. Long service life

The drums can be utilized for up to 10 trips, depending on the

products packed and transport conditions. It is important,

however to refill the drums with the same product or substance

of the same product group. Before every shipment, closures and

seals have to be checked and replaced if necessary.

6. Inert, corrosion free

Minimal risk of product contamination even under extreme

climatic conditions and when stored outside.

7. Suitable for hot fill products

The drums may be used for hot fill products of up to 80°C.

Special venting caps are recommended to avoid a vacuuming

effect.

8. Suitable for gaseous substances

Special degasifying closures are available for the tighthead LRing

drums and are liquid-tight to avoid the build-up of

overpressure.

9. Space saving qualities

Dimensional compatibility for loading into international freight

containers.

10. Product marking

Identification by means of silkscreen printing, stenciling and

labelling is possible.

11. Visually attractive

Less susceptible to impact damage than steel drums. The drums

do not require repainting.

OUTSTANDING STABILITY & STACKING PERFORMANCE

TEST REQUIREMENT

CONTACT US

Taiko Drum Industries Sdn. Bhd. (Factory)

[198101012597 (78727-A)]

Lot 19, Fasa II, Tangga Batu Industrial Estate,

76400 Melaka,

Malaysia.

+60 6-351 3088 / 351 3089 / 351 0823

+60 6-351 3091

tdi.mkt@taiko.com.my

Ms. Annie Ee

Taiko Drum Industries Pte. Ltd.

73B Neil Road,

088901 Singapore..

+65-6327 2480

+65-6327 2482

drums@taikogroup.net